Subsequently are the most prominent features which are motivated by the dod described. Of course there are far more details which changed over time. I highly recommend all the listed literature (see section Literature / External links).

The rear panel

One of the most striking details linked to this dod is the rear panel.

In July 1942 several changes applied to the rear panel:

- introduction of the trailer socket

- movement of the rear reflectors to a lower position

- phasing out of the Willys-script

- introduction of the eye-bolts to the pintle hook

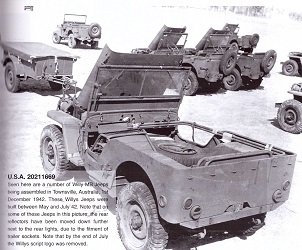

The first volume of "the standardised war-time jeep" by John Farley provides some information on these changes. The book contains the following picture:

The caption of the picture states: "Seen here are a number of Willys MB Jeeps being assembled in Townsville, Australia, 1st December 1942. These

Willys Jeeps were built between May and July '42. Note that on some of these Jeeps in this picture, the rear reflectors have been moved down

further next to the rear lights, due to the fitment of trailer sockets. Note that by the end of July the Willys script logo was removed."

(Farl02, p.105). The book furtermore states that "another change in July was the standard fitment of the trailer electric coupling socket"

(Farl02, p. 109) and "Part number 1502 Pintle hook was also changed, it now had two bolt eyes and safety chain fitted after Willys MB

number 158372." (Farl02, p.109)

In the second volume of "the standardised war-time jeep" John Farley provides a more detailed on look on the picture already shown in the first

volume (see above).

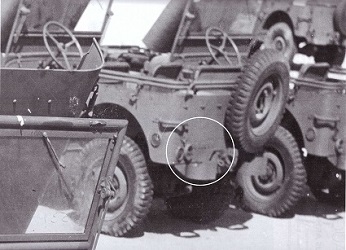

The following picture from the second volume is in fact a zoomed version of the above picture of volume one.

It shows a Jeep that has the Willys script as well as the trailer socket. Since the trailer socket is placed where previously the rear reflectors were,

the reflectors were moved to a lower position.

The book of Becker and Dentzer states that "there is no trailer socket until serial number 200678 (January 1943)" (BeDe94, p.78). This book also describes that "the Willys-logo is pressed beside the spare tire until about serial number 146290

(May 1942)" (BeDe94, p.78).Therefore this book contradicts the data in the two Farley books and indicates that the Willys script was phased out

already before the dod of MB158963 and the trailer socket was introduced far after the dod of MB158963.

In the second volume of "All-American Wonder" by Ray Cowdery also some information is included about the introduction of the eye bolts: "The first type

[of pintle hook] had no chain eyes for trailer safety chains. They were an afterthought added after MB 158372 in July 1942" (Cowd03, p.246). This fits

with the information from the first Farley book.

Finally in the 4th volume of "the evolution of the Willys-Overland MB Jeep" by Lloyd White an official document by Willys-Overland with changes on the

Willys MB jeep is presented. This document is dated November 3, 1944 and is signed by D.G. Roos, Vice President in charge of Engineering. In this

document more than 250 changes to the Willys MB Jeep are documented. Amongst others this document provides the folliwing information (WhV415, p.75):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 5 |

Additions and Revisions Necessary For Trailer Use. Requested By - U.S. Goverment (Q.M.C.) to accomodate trailer equipment. Addition of electric socket assembly, cable, eyebolts and resultant changes in wiring harness, frame reinforcements, rear and side body panels and reflectors relocated. (To accommodate trailer equipment). |

7-10-42 | 5-25-42 | 6-1-42 |

| [...] | [...] | [...] | [...] | [...] |

This table indicates that the introduction of the trailer socket and the eye bolts as well as the repositioning of the rear reflectors took place on

10th July 1942 and thus before the dod of MB158963 and seems to be consitent with the information from both Farley books.

All the above information shows that there are some contradictions within literature. Nevertheless, based on all the quoted information, I decided

that it seems to be most plausible, that at the dod of MB158963 the Willys script still existed and the trailer socket already has been introduced

and I wanted to reproduce these two characteristics.

The repro-tub that I got was a late type. The rear panel therefore only had the trailer socket. In order to realize the correct rear panel, I bought an additional rear panel

with the willys script and inserted the hole for the trailer socket by myself.

Afterwards I removed the script-less rear panel from the tub, by drilling the spot welds. A friend welded the new script rear panel with the self-made trailer socket to the tub.

I still think the result is really good.

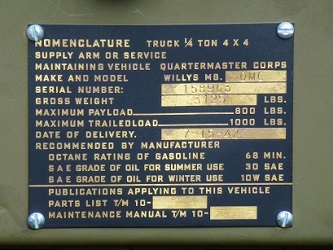

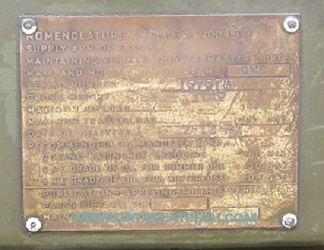

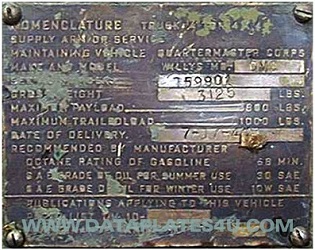

Dataplates

Since the original tub and thus also the original dataplates on the glove box, I had to order repro dataplates. I ordered my plates at

www.dataplates4u.com. The pictures below show my dataplates.

dataplates4u has a database with pictures of original dataplates. Before they stamped my data plates, they sent me pictures of the two dataplates from their database, closest to MB158963.

The pictures showe in both cases that the nomenclature plate was stamped with "QMC" (Quartermaster Corps).

This indicates that the jeeps in this serial number range indeed were produced for an US Army

contract.

Since this seems to be true, I decided to stamp my nomenclature plate with "QMC", too. Although this does not fit to a british jeep, since british contract normaly were stamped

"BRT". Thus, this detail refers to the dod and does not fit to the overal british jeep.

Furthermore the pictures reveale that both nomenclature plates are of the early type, without the "Willys" script printed on the plate.

"Contract DA-W-398-QM-189 pertained to the British, Russian and Chinese jeeps which were basically an export version of a standard MB jeep. [...]

The 'DA' of this contract stood for 'Defense Aid' and was part of the pre-war Lend Lease efforts by the US to aid our Allies by fulfilling their

light vehicle needs. The challange was that the initial quantities were contracted before the U.S. entered World War II on December 8, 1941. Once

the United States entered the war, the US Army and US War Department reassessed their needs and adjustments were subsequently made to these

export contracts.

In factory documents these contract requirements were identified by 'MB' followed by a dash then the three letter abreviation for their country

as follows: BRT (Britain), RUS (Russian), CHI (China) and CAN (Canadian). These three letter country abbreviations were stamped on the name plates

as the model name for these jeeps except for the Canadian jeeps which had their own name plate. None of these versions had any mechanical

requirements that deviated from the standard production Model MB." (WhV114, p. 368)

"The british contract jeeps were ordered on their primary contract SM 2275. SM stood for Supply Mechanical and the initial requesst was for

80,000 jeeps. In 1943 this quantity was reduced to 40,000. There were also a series of subsequent smaller quantity contracts as the need was refined.

In order to fulfill the demand in a timely manner reconditioned jeeps were accepted and called out in modifications to this main contract. It is

only a best quess as to the final number of jeeps that were delivered or transferred during the war, 80,000 was probably the amount for all

contracts for the British and Commonwealth forces combined. This included Canada's needs after their specific contracts were completed.

Any physical modifications or changes to these BRT MB's were done by the British upon receipt. As fas as Willys was concerned, these jeeps were

standard production MB's that were painted A-2531 lusterless olive drab and the 'S' for suppression painted in blue drab on the cowl. These contracts

were fulfilled with both slat grille and stamped grille MB's.

With the best of intentions, the 'mystery box' on the current production data plate (A-1329, A-8175 or A-11757) was stamped BRT to identify these

jeeps as British instead of QMC or ORD. The reason I state that BRT is stamped in the 'mystery box' with the best of intentions is that many of

these BRT jeeps never left the United States. Given that they were actually U.S. contract jeeps with a BRT stamp, any jeep could be used to

fulfill an order and not deviate from the contract requirements. These jeeps used the standard A-1330 Caution plate and the A-1331 Shifting plate.

The first 10,034 BRT jeeps had U.S.A. registration numbers 2078697 to 2088730 (inclusive) painted in blue drab on the hood sides but not on the

rear panel. No U.S.A. stars were painted on their side panels. Later BRT jeeps did not have any U.S.A. registration number painted on the hood

sides or stars on their side panels. BRT jeeps that did not have a 'U.S.A. number' received a British census (W.D.) number painted in white on

both sides of the hood and on the rear panel below the footman loops for the top on early versions that did not have the provision for the fuel

can carrier." (WhV114, p. 369)

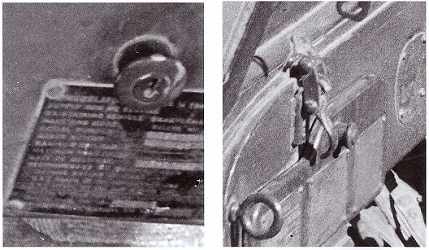

Glove compartment

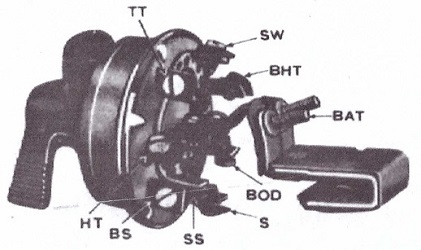

According to the second Farley book at MB137909 in April 1942 "A3823 latch lock [...] replaced keylock A-3532 [...] on the glove compartment." (Farl09, p.38). The picture below shows both types of compartment locks.

This suits to the information provided by the 4th volume of "The evolution of the Willys-Overland MB Jeep" by Lloyd White (WhV415, p.77):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 15 |

Glove compartment lock Requested by - U.S. Government. Q.M.C. To furnish push button type lock and knob on glove compartment door in lieu of key type lock. (To eliminate key lock). |

4-23-42 | 2-21-42 | 2-21-42 |

| [...] | [...] | [...] | [...] | [...] |

Based on this information I installed the latch lock on the glove compartment.

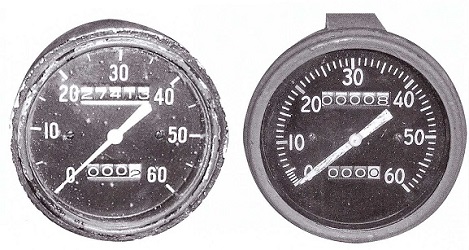

Speedometer

In April 1942 from MB137760 on A5734 speedo [...] featuring one-mile increments on the face replaced A1266 Auto-Lite SPK-4001B [without one-mile increments]. (Farl09, p.38).

-

left side: Auto-Lite SPK-4001B without one-mile increments

right side: A5734 speedo with one-mile increments

(Source: Farl09, p.38)

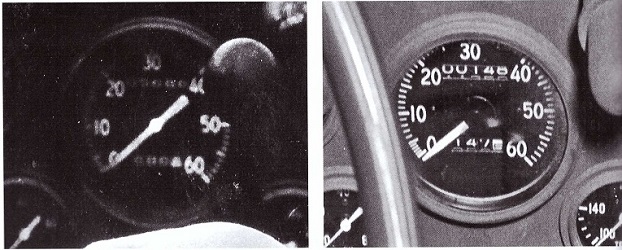

In June 1943 "the speedometer A5734 ASLBK4003 made by Auto Lite [...] was changed to a waterproof model A8180 KS40355 made by King Seely [...] with a black counterbalance indicator needle. There were other manufacturers of both varieties." (Farl09, p.94).

-

left side: Auto-Lite A5734 ALBSK4003 speedo with one-mile increments

right side: A8180 KS40355 speedo with black counterbalance indicator needle

(Source: Farl09, p.94)

Again, this information is confirmed in the 4th volume of Lloyd White's books left (WhV415, p.86):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 89 |

Speedometer Needle Revision Requested by - Ordnance Department change order. Revision of speedometer needle by shortening tail. (To avoid covering of trip odometer). |

3-31-43 | 4-7-43 | 3-16-43 |

| [...] | [...] | [...] | [...] | [...] |

Thus, for MB158963 the A5734 speedometer with long needle and one-mile increments was the correct speedo-version.

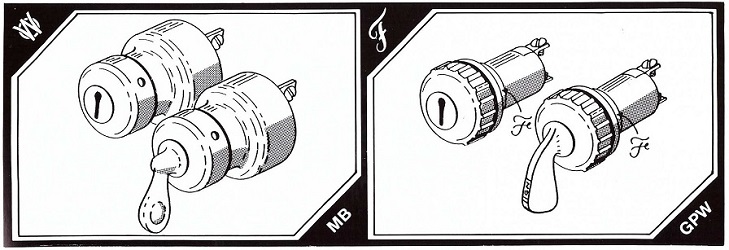

Ignition switch

In January 1943 "at MB202023 the ignition switch changed from key-type to toggle switch [...]." (Farl09, p.81). The book "All-American Wonder Volume 2"

by Ray Cowdery gives similar information. Only the date differs by one month. "MBs up to serial number 202023 (December 1942) used the A-2517 key type

ignition switch. After that they used the A-6811 'handle' type ignition switch assembly [...]." (Cowd03, p.189).

However, at the dod of MB158963 the key-type ignition switch with the standard H700-key was installed in the factory. The All-American Wonder book also

gives some important information about the differences between Willys and Ford ignition switches. "Ford bezels have little bumps around their

circumference to make them easy to install and remove while Willys bezels have 2 holes in the side so they need to be tightened or loosened with a

1 1/4 inch spanner wrench." (Cowd03, p.189). These differences are also shown in the pictures.

The 4th volume of Lloyd White's books states, that the change took place in October 1942 left (WhV415, p.80):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 30 |

Ignition Lock Elimination Requested by - U.S. Government. Ord. Dept. Release of keyless type ignition switch in place of key type. (To reduce amount of keys required per vehicle). |

10-2-42 | 9-30-42 | 8-31-42 |

| [...] | [...] | [...] | [...] | [...] |

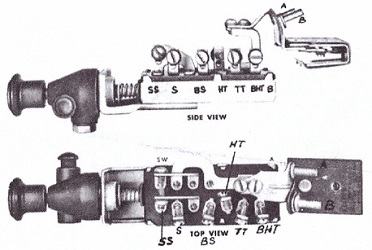

Light switch

Also the light switch changed over time. The second Farley book states that in July 1944 "the blackout main light switch (push-pull type) was replaced during this month by the rotary light switch [...]" (Farl09, p. 126). The pictured show these different types.

The 4th volume of Lloyd White's books states that the light switch changed in March 1944 left (WhV415, p. 93):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 140 |

Rotary Blackout Lighting Switch Requested by - Ordnance Department change orders. Releasing of rotary blackout lighting switch and cancelling the former push-pull type, together with consequent changes. (To meet Government requirements). Note: Later supplement #1 was issued and approved, removing luminous paint from rotary blackout switch handle, per Government requirments. |

3-10-44 | 9-22-43 | 10-8-43 |

| [...] | [...] | [...] | [...] | [...] |

The correct type of main light switch for MB158963 was the push-pull type.

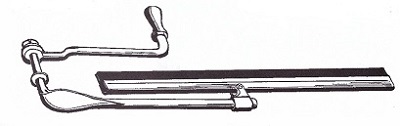

Windscreen wipers

According to the book of Becker and Dentzer the first model of wipers was used from 1941-1943. The following picture shows the first model (single) wiper.

The 4th volume of Lloyd White's books confirms the date (WhV415, p.86):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 91 |

Tandem Windshield Wiper in Production Requested by - Ordnance Department change order. Tandem control of windshield wiper made by flattening a section of the present handle and attaching a tie bar from the right to left handle. (To provide for tandem windshield wiper operation per Government change order). |

8-14-43 |

4-2-43 8-14-43 |

4-30-43 |

| [...] | [...] | [...] | [...] | [...] |

This information is proved by the second Farley book. The following picture shows the second wiper model - the tandem wiper assembley - which was not introduced

until August 1943.

The information shows that for MB158963 the single wiper was the model which was installed in the factory. For this reason I also installed single wipers in the jeep.

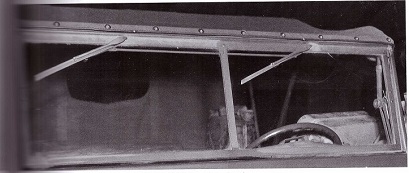

Rifle rack mounting brackets

There are many pictures of jeeps with the rifle holder installed inside of the windshield. According to the second book of Farley the rifle holder was introduced in September

1943. The picture shows the rifle rack mounting brackets on the inside of the windshield.

The 4th volume of Lloyd White's books confirms the information (WhV415, p. 85):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 81 |

Universal Rifle Bracket Requested By - Ordnance Department 1/19/43. Addition of Universal rifle bracket in accordance Government specifications to be furnished and mounted on back face of windshield panel. Note: - Later there was added to the rifle bracket a zippered canvas cover and still later a change was made to prevent marking of rifle by sharp projections, by grinding off ends of stapling cover bracket. (To provide Universal rifle bracket and cover per Government Requirements). |

9-14-43 8-20-43 |

3-4-43 | 7-9-43 |

| [...] | [...] | [...] | [...] | [...] |

Before this date, the rifle brackets were not installed in the factory.

My reproduction winshield had the windshield brackets installed. Because of the above information I removed them, since they were not appropriate

for the dod of mid-July 1942.

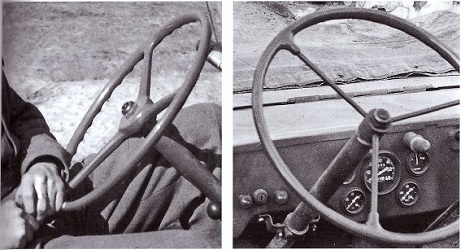

Steering wheel and rubber parts

Due to rubber shortages over time several rubber parts were omitted or substituted by other materials.

The most striking rubber part certainly is the steering wheel. It changed several times. According to the second book of Farley "somtetime between

late March and mid-April [1942], Willys started to change the steering wheel from black to green." (Farl09, p.38). Later on in september 1942

"the steering wheel A535 green rubber changed to A6558 with a composite green rim and metal spokes." (Farl09, p.73). The picture shows both types

of steering wheels.

-

left side: rubber steering wheele

right side: steering wheel with metal spokes

(Source: Farl09, p.73)

The 4th volume of Lloyd White's books confirms the information left (WhV415, p. 81):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 39 |

Tenite Steering Wheel (Conservation of Tenite) Requested by - U.S. Government Ord. Dept. Changing materialfrom Tenite to Semi-Tenite) (To conserve Tenite) |

9-16-42 | 8-20-42 | 8-24-42 |

| [...] | [...] | [...] | [...] | [...] |

When I bought the chassis in 2010, the later version with metal spokes was installed. Since the black rubber steering wheel was already phased out

before the dod of MB158963, the green rubber version was the correct one. I managed to find an original green "Sheller" rubber steering wheele and

installed this on the jeep.

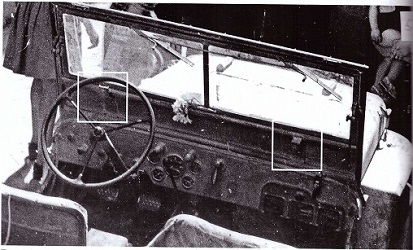

The following picture shows the single wipers, the missing rifle rack mounting brackets as well as the green rubber steering wheel and the

latch lock on the glove compartment.

-

Single windscreen wipers,

removed rifle rack mounting brackets,

green rubber steering wheel,

latch lock on glove compartment

Beside the the steering wheel there are also other rubber parts, which were replaced over time. These include the hood blocks. "The green rubber hood blocks A922 [...] changed to an all wood version A3780 [...]" (Farl09, p.66) at the beginning of september 1942. These different hood blocks are shown below.

The 4th volume of Lloyd White's books confirms the date (WhV415, p.77):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 6j |

Hood Windshield Bumper (Conservation of Rubber) Requested by - U.S. Government. Q.M.C. Substitution of suitable material in place of rubber for the bumper. (To conserve crude rubber). |

9-24-42 | 9-24-42 | 9-24-42 |

| [...] | [...] | [...] | [...] | [...] |

Since the production change took place after the dod of MB158963, I installed rubber hood blocks on MB158963.

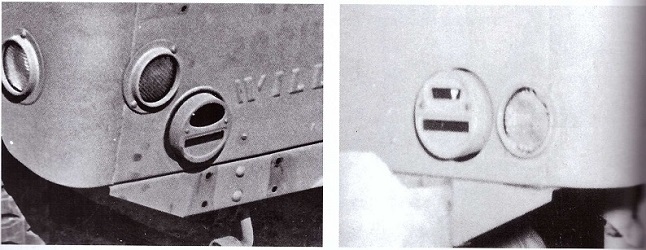

In September 1942 "the rubber grommet [...] around the rear lights began to be phased out [...]" (Farl09, p.66). The picture below shows the differences.

-

left side: rear light with rubber grommet

right side: rear light without rubber grommet

(Source: Farl09, p.66)

The 4th volume of Lloyd White's books confirms the date (WhV415, p.76):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 6h |

Tail Lamp Grommet (Conservation of rubber) Requested by - U.S. Government. Q.M.C. This change eliminates the grommet (tail lamp to body). (To conserve crude rubber) |

9-23-42 | 9-23-42 | 9-23-42 |

| [...] | [...] | [...] | [...] | [...] |

This production change also is not applicable for MB158963. Therefore I installed the rubber grommets around the rear lights.

In August the lever seals were changed from rubber to leather (WhV415, p.76):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 6e |

Lever Seal (Conservation of Rubber) Requested By - U.S. Government. Q.M.C. On each of the following parts rubber has been eliminated and leather specified: Transfer Shift Lever Grommet Accelerator Treadle Rod Floor Seal Gear Shift Lever Housing Cover (To conserve crude rubber) |

8-28-42 | 4-9-42 | 4-17-42 |

| [...] | [...] | [...] | [...] | [...] |

Since this change took place after the dod of MB158963, I installed the rubber grommets.

Furthermore several seals changed from rubber to hair felt already in July 1942:

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 6f |

Compartment Door Seal (Conservation of Rubber) Requested By - U.S. Government. Q.M.C. In each of the following parts rubber has been eliminated and saturated hair felt specified: Tool Compartment Lid Seal Glove Compartment Door Seal (To conserve crude rubber) |

7-2-42 | 5-4-42 | 5-9-42 |

| [...] | [...] | [...] | [...] | [...] |

Since these changes started in production already in early July I installed the hair felt parts on the Jeep.

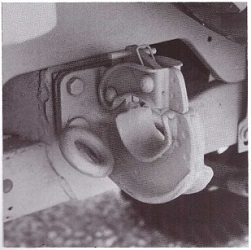

Pintle hook

"At MB158372 two safety eye-bolts A6019 were attached to the pintle hook." (Farl09, p.61). The book All-American Wonder Volume 2 gives the same information. "Style 1 [...] which is sort of generic cast steel pintle hook found on most Willys MB 1/4 tons. [...] The first type had no chain eyes for trailer safety chains. They were an afterthought added after MB 158372 in July 1942. [...] The 3rd style shown here is a late-war innovation - a pintle hook made up of pieces of stamped steel. [...]" (Cowd03, p.246).

According to the 4th volume of Lloyd White's books the change to the late style pintle hook took place in June 1944 (WhV415, p.101):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 188 |

Pintle Hook Assembly Requested by - Willys-Overland To provide a steel stamping type of pintle hook as optional with present steel or forged types. (To ease the casting situation and reduce costs). |

6-12-44 | 5-2-44 | 11-1-44 |

| [...] | [...] | [...] | [...] | [...] |

The following picture shows the pintle hook on MB158963. Since it was produced after MB158372, the safety eye-bolts are installed.

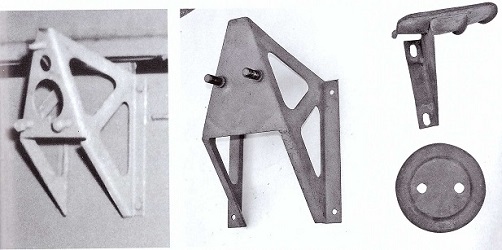

Spare tire carrier

Another detail on the tub because of the dod is the spare wheel carrier. "During the month of October 1943 the three-stud carrier A2359 [...]

changed to a two-stud carrier WO-A-11701 [...] with retaining disc and spare tyre support bracket. [...]" (Farl09, p.107).

-

left side: three-stud carrier

right side: two-stud carrier with retaining disc and support bracket

(Source: Farl09, p.107)

According to the 4th volume of Lloyd White's books the spare tire carrier changed in November 1943 (WhV415, p.89):

| ITEM | TITLE |

DATE STARTED IN PRODUCTION |

DATE ITEM FORM SUBMITTED TO U.S.GOVT. |

DATE U.S.GOVT. APPROVAL |

|---|---|---|---|---|

| [...] | [...] | [...] | [...] | [...] |

| 115 |

Spare Tire Support Requested by - U.S. Government Ord. Dept. Change in construction in the spare wheel support bracket and adding a spare tire support. (To divide the load on the spare tire carrier between the body and frame, thereby avoiding possible failure of the spare tire carrier). |

11-3-43 | 6-24-43 | 8-28-43 |

| [...] | [...] | [...] | [...] | [...] |

Thus, for MB158963 the earlier three-stud spare tyre carrier is correct and I installed this one on the jeep.